Legacy

Born to serve

Decades ago a few skilled tool and die makers decided to go it alone, investing their life savings in a few "Eyelet Machines" to manufacture a new future for the families. Explore our milestones and rich history to learn more about what makes Cly-Del Manufacturing the company it is today.

1800’s

The Connecticut Yankee has long been a symbol of ingenuity and inventiveness. These qualities have been matched by production skills since the earliest days. From colonial times, Connecticut has been predominantly a manufacturing state and a world leader in industrial development.

When Connecticut was still a colony, her factories were already important enough to draw angry complaints from competitors in England. Connecticut metal buttons were replacing the imported product and were providing the start of Connecticut’s great brass industry.

Connecticut is often described as the "Arsenal of the Nation." It gained this reputation as early as the American Revolution. Early in the 19th century, Eli Whitney and Simeon North began making Connecticut firearms with interchangeable parts. This is generally recognized as the beginning of modern mass production.

Through the years, Connecticut's industrial pioneers have given the world inventions such as vulcanized rubber, friction matches, sewing machines, steamboats, safety fuses, lollipops, corkscrews, mechanical calculators, cylindrical locks, and the submarine.

Incorporated as a town in 1686 and as a city in 1853, Waterbury is named for its abundant waterways. It is nicknamed the Brass City and was once the center of the American brass industry, employing a peak of 50,000 brass workers during World War II. The Naugatuck Valley became the epicenter of tool and die making, and to this day, its concentration of master craftsmen and skilled workers remains unmatched.

George M. Pratt, inspired by the Palmer System, received patent #202,866 on March 23, 1878, for an enhanced micrometer. Initially assigned to the Victor Sewing Machine Company of Middletown, Connecticut, the patent was later acquired by Brown & Sharpe, who further perfected this fundamental measuring tool. The micrometer, born out of necessity, has undeniably revolutionized precision machining and toolmaking, significantly elevating industry standards for product quality.

1930’s

Now entering the thirties when everyone was listening to Fred Allen, Bing Crosby, the Goldbergs, and Walter Winchell on the radio…

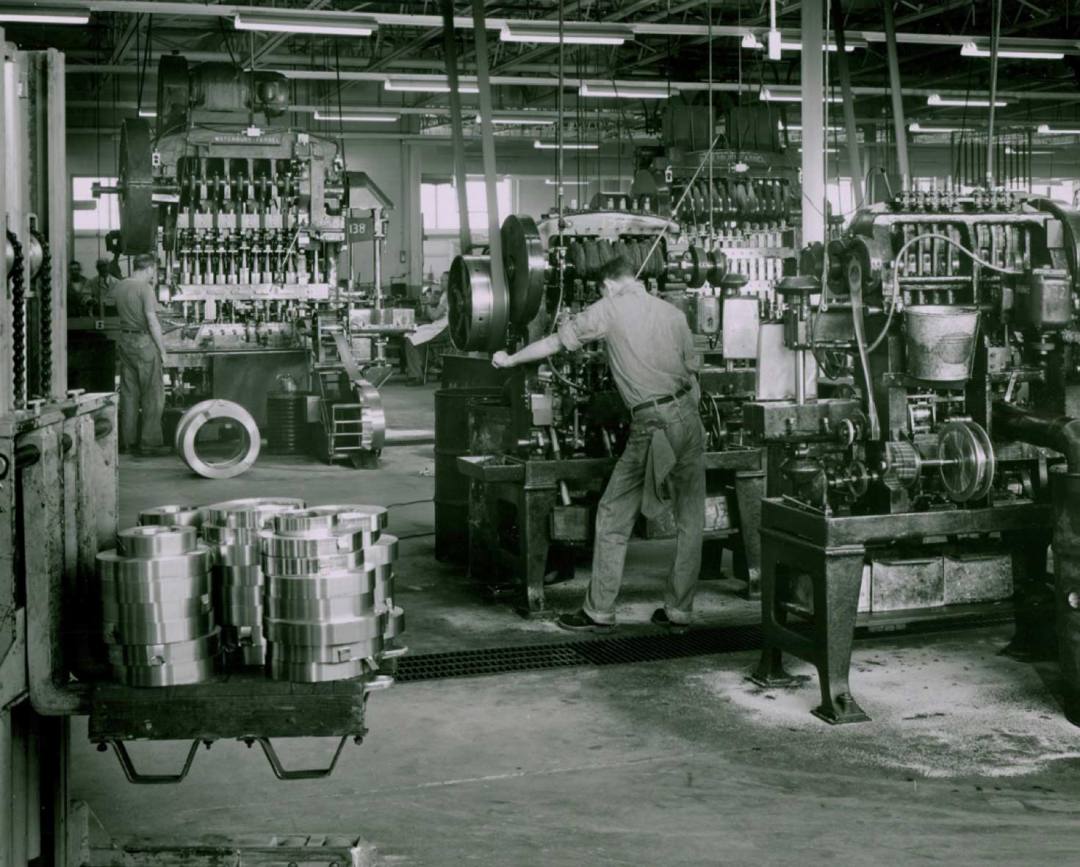

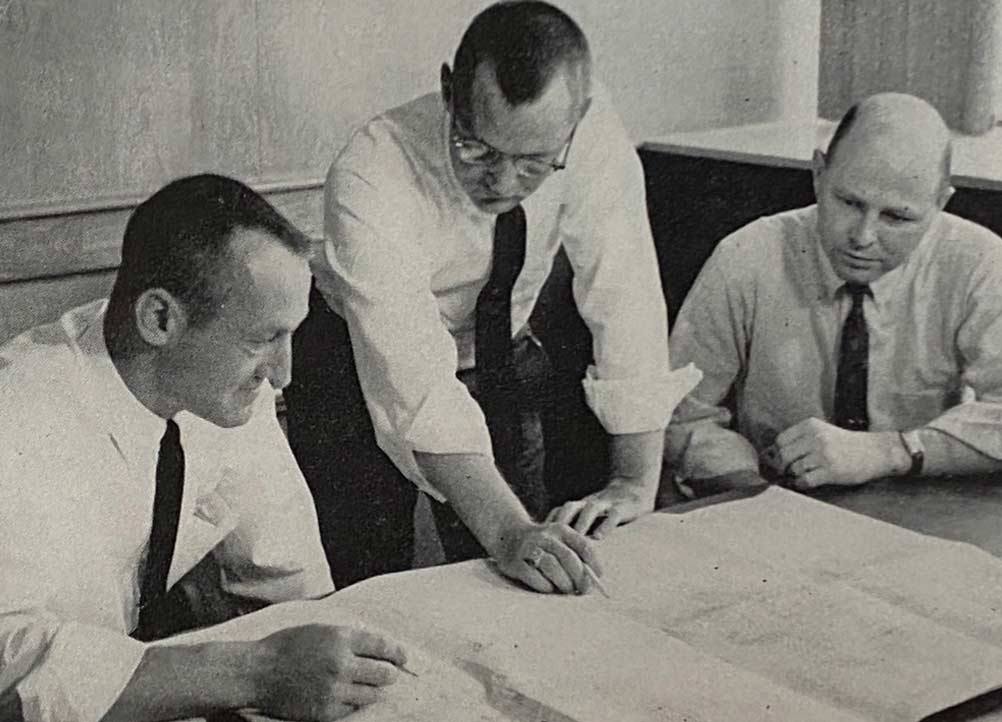

Modern America as we know it was quickly taking shape fueled by vigor and determination post-depression. Two bright and entrepreneurial toolmakers, Clyde W. Garthwait & Adelbert C. Traver invested their life savings in an "Eyelet Machine" to manufacture a new future for the families. Prior, Clyde was formerly associated, for 20 years, with Mattatuck Manufacturing. Together, they started moonlighting in a small rented garage in West Cheshire, Connecticut using only the essential tools of the trade. Soon after, The Cly-Del Manufacturing Company was born. The name derived from the two original founders' first names Clyde (Cly) and Adelbert (Del).

October 13, 1939

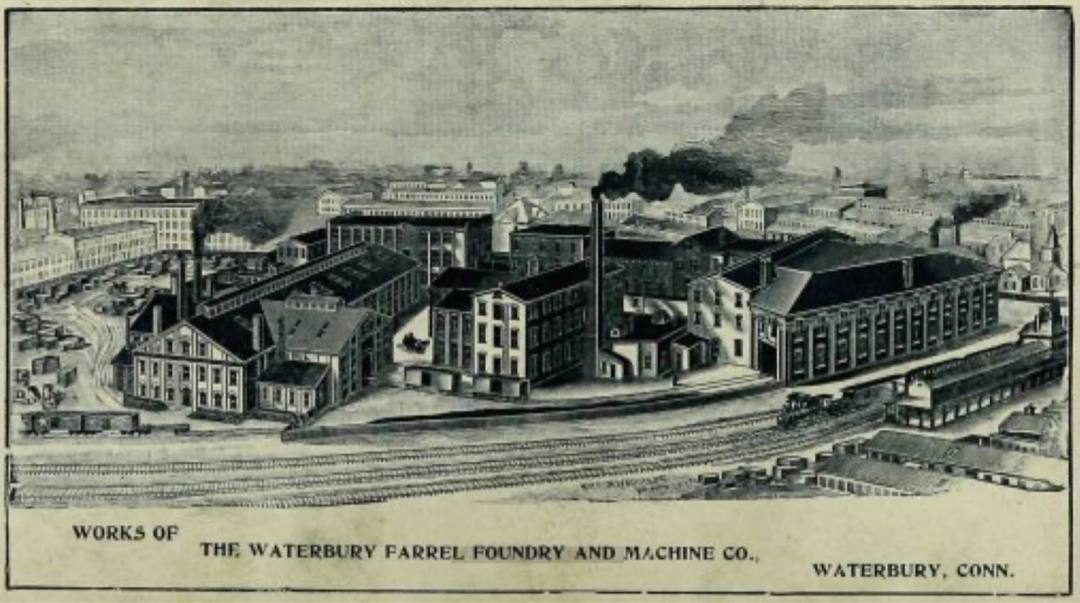

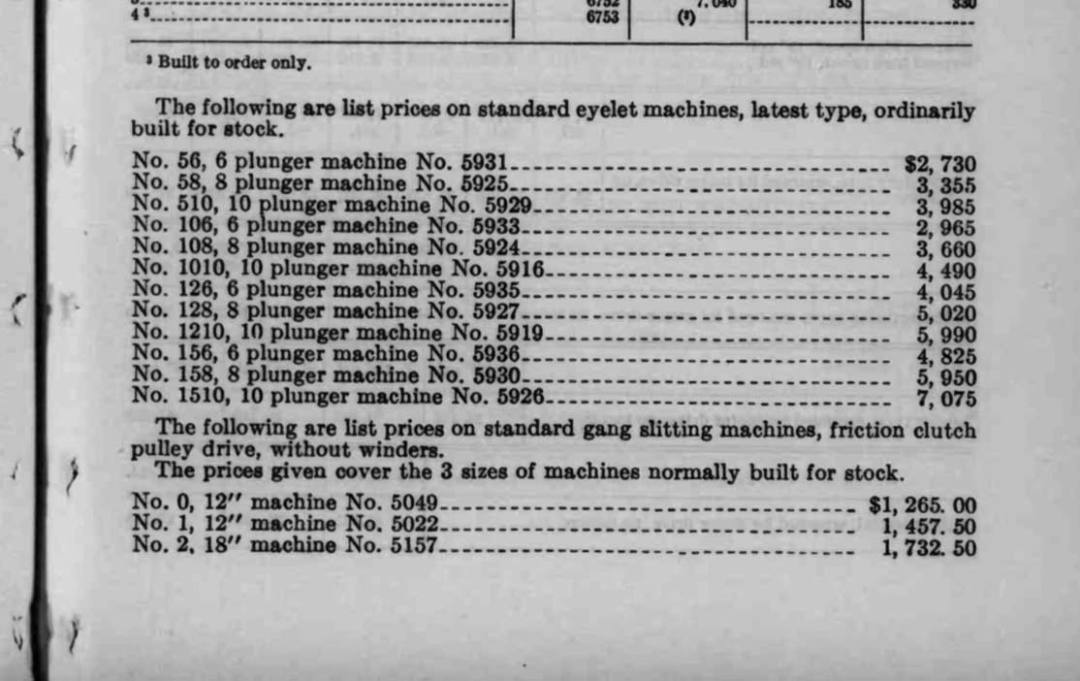

The original corporate minutes book contains the State of Connecticut Certificate of Incorporation which was received and filed on October 13, 1939. The first minutes explain the nature of Cly-Del's business to be the "'manufacture of all kinds of small articles composed chiefly of metal." The first major expenditure detailed in the 1939 minutes was for a 15-8 eyelet machine made by the Waterbury Farrel Foundry and Machine Company; the price: $5,090 and initial production commenced.

1940’s

January 27th, 1940

The first official employee was hired, a tool maker named Rudolphe Desaulniers. Desaulniers came to Waterbury in 1924 from St Flores, Canada. He was a professional Boxing champion and ranked among the top 10 Flyweights in the world.

WWII

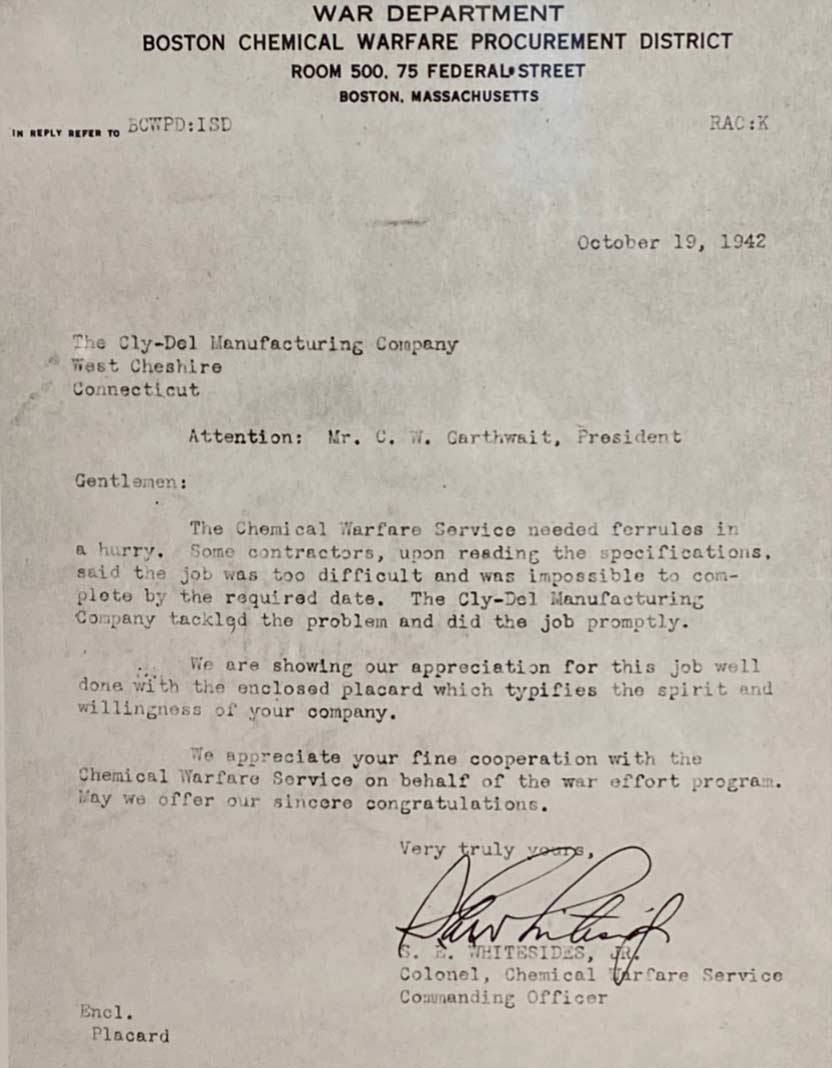

Cly-Del helped to supply the U.S. with war-related drawn metal parts and components for the department of defense. By establishing and exceeding quality standards, Cly-Del converted the company’s production capabilities to meet military requirements.

1945

The former Matthews & Williard Plant located on Maple, North Elm, Kingsbury streets and Cherry avenue which has been purchased by The Cly-Del Manufacturing Company, from the Scovill Mfg. Co., for an approximate price of $60.000. About 120,000 square feet was involved in the transaction.

November 19th 1945

Clyde’s partner and second original founder of Cly-Del, Adelbert (Del) Traver, left for other expenditures. The Garthwait family became the official owner of the company.

After the war, Cly-Del grew operating capabilities in the production of eyelets, stampings and drawing parts.

1946

Clyde's son Robert W. Garthwait Sr. returns from his post in Panama and joins the company working alongside his father, Clyde, and brother Clyde Jr.

1947

Begins making battery components for P. R. Mallory and Co. Inc. which was purchased by Dart Industries in 1978 and renamed Duracell after its alkaline battery brand.

1949

Filed for patent 2,510,569: Liberty bell: a bell which has a shape of the flared or Liberty bell type, and which is adapted to be economically formed from sheet metal.

Filed for patent 2,612,336. Broom cap: caps for the ends of broom handles, and more particularly to a broom cap of the type which has a swingable bail or loop for suspending the broom upon a hook.

1950’s

1951

Filed for patent 2,722,005: A machine for automatically assembling wire bails on caps of the type commonly used on the ends of the handles of brooms, whisk brooms, mops etc.

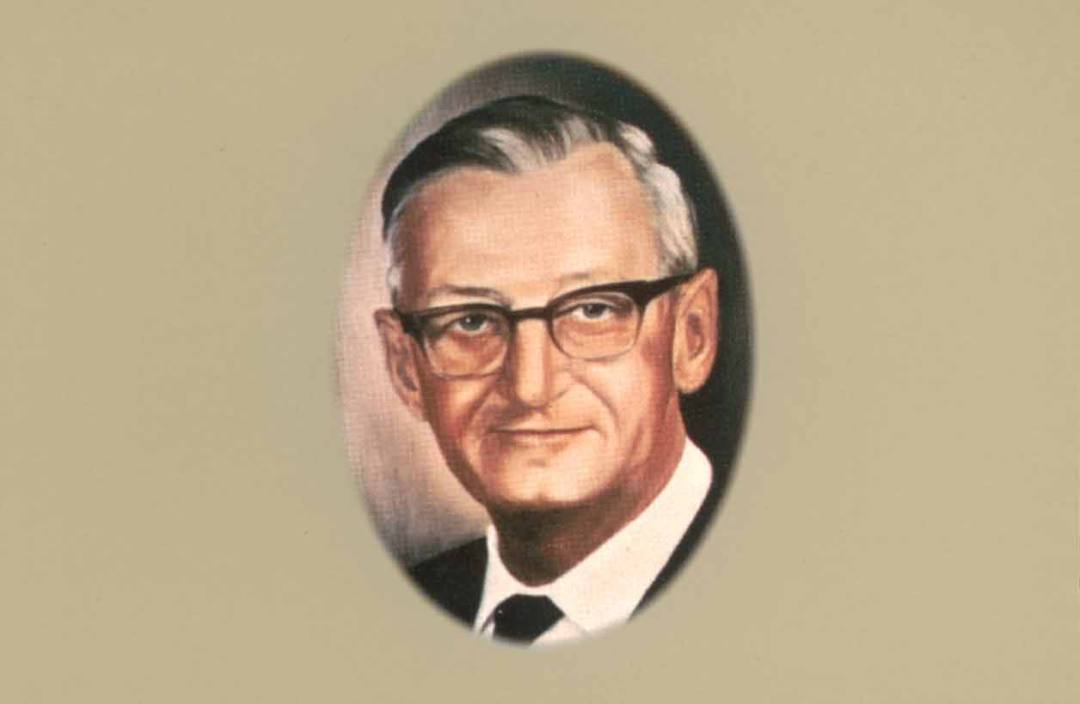

Clyde’s son Robert W. Garthwait filled the top management positions, continuing the family owned legacy.

Clyde’s son Clyde Garthwait Jr. incorporated The Connecticut Eyelet Company, on Sep 18, 1951

By the 1950s, domestic demand for consumer goods such as televisions and cars had increased giving momentum to the manufacturing sector. Against this backdrop, mass production had started, and in the process stimulated the economy in Japan. To achieve the goals of a large scale production, all parts were made within much tighter tolerances. Statistical Process Control to manage production runs and rational approaches in manufacturing took the centerstage during this period.

1955

On 11 August 1955, Hurricane Connie, which had already dumped a great deal of rain in the North East, had brushed the North West tip of Connecticut and saturated the grounds in Winsted and surrounding towns. Less than a week later, Hurricane Diane arrived in Connecticut after damaging Washington D.C. and New York City. The normally placid Naugatuck River, swelled by the driving rains, overflowed its banks cresting over 25 feet above its average water level, setting the stage for one of the worst disasters ever to hit Waterbury and the state of Connecticut. In Connecticut, it's simply known as the Flood of '55. Others remember it as "Black Friday."

1956

During the flood the Garthwait’s came out to a large pasture on Lovers Lane, now named Sharon Road after one of the family members in Waterbury. The site measured 4-6 feet above the flood high water mark. The selected site is still where we call home today. Our current facility is the result of 11 expansions adding 150,000 square feet of additional manufacturing space to the original 50,000 sq ft building.

Filed for patent 2,800,870: This invention relates to bells, and more particularly to a bell and clapper assembly comprising only two parts which can be quickly and easily assembled, and is an improvement over the bell disclosed and claimed in the United States Patent No. 2,510,569, issued to Clyde W. Garthwait, on June 6, 1950.

60's-80’s

1960

We became suppliers of Durcell, Energizer and Rayovac. Over time, we became the sole/primary supplier for Durcell in North America and have been making parts for them since they were P.R. Mallory in 1947.

1973

Filed for patent 4,277,298: A method of making a hollow article with a fluorocarbon layer bonded thereto.

1974

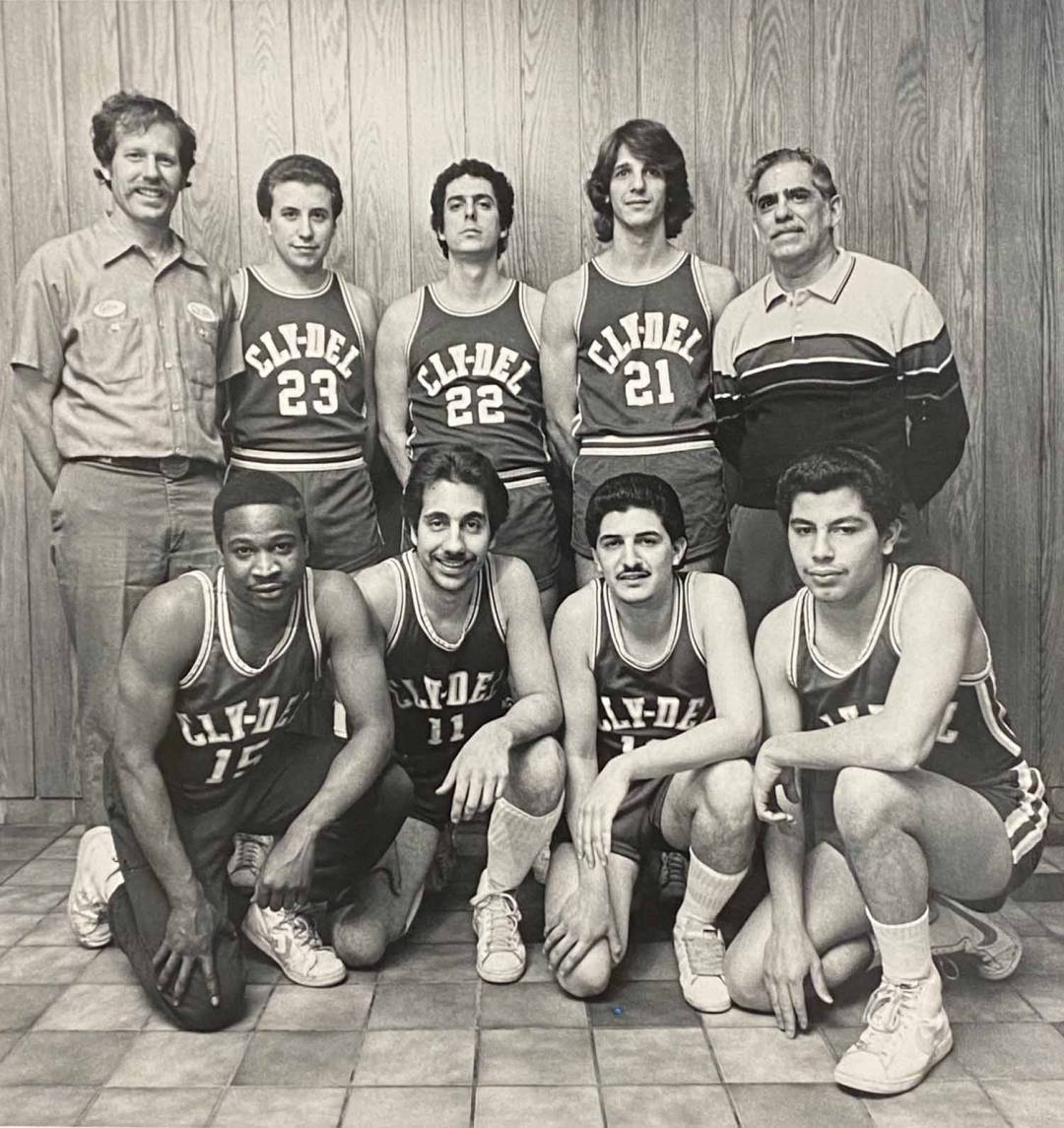

Robert’s son, Robert (Bob) W. Garthwait Jr. entered the Cy-Del workforce with a humble position assisting the groundskeepers by cutting the grass. Today, Bob Jr. guides our company as Cly-Del's President & CEO.

1975

July 16th 1975: The passing of founder Clyde W. Garthwait Sr.

1976

Bob Garthwait Jr. made it into the building working in Shipping and Receiving on a pack-line. Worked continued during the summers while he attended Gettysburg College, preparing to formally take on his career at Cly-Del Manufacturing.

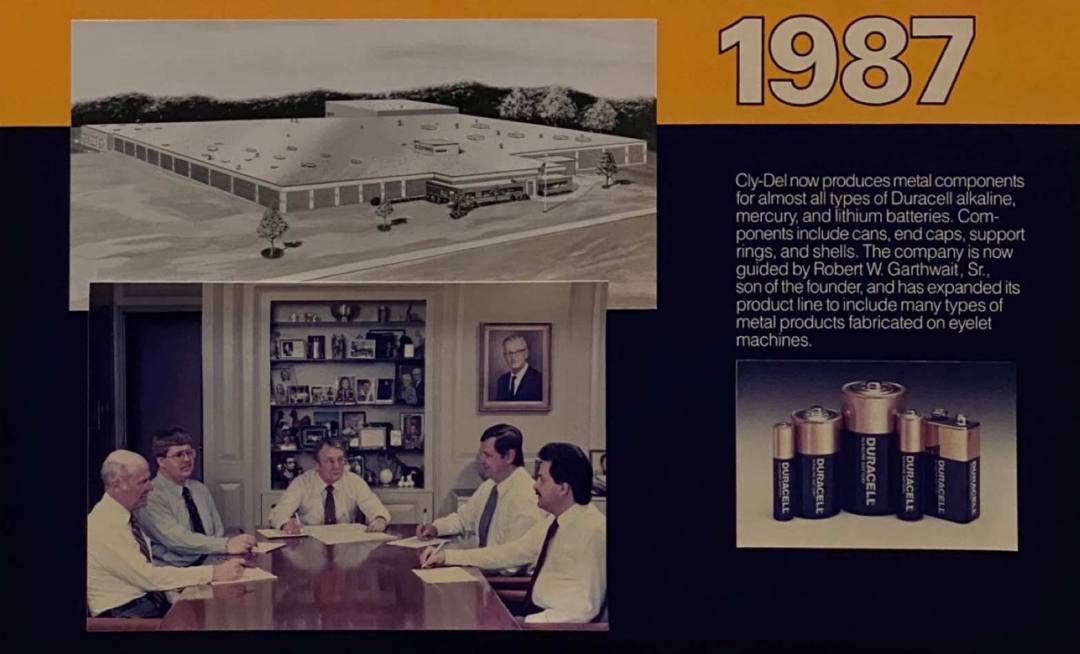

1987

Cly-Del created a new word: "Eyeletype." For all the years previous, Cly-Del was often incorrectly referred to as an eyelet company, because the type of presses used at Cly-Del appeared similar to presses that produced eyelets for shoes and for reinforcing tent rope holes in canvas. This misnomer was corrected with the new word, "Eyeletype," which is now a trademark of the company.

Filed for patent 4,708,043: Adjustable cam indexing feed apparatus that forwardly and laterally indexes a strip provided with an angular blanking pattern along a zigzag path via an adjustable indexing cam mechanism.

Cly-Del receives the Duracell The Outstanding Supplier Award.

1989

Cly-Del celebrates its fifty year anniversary.

1990’s

1992

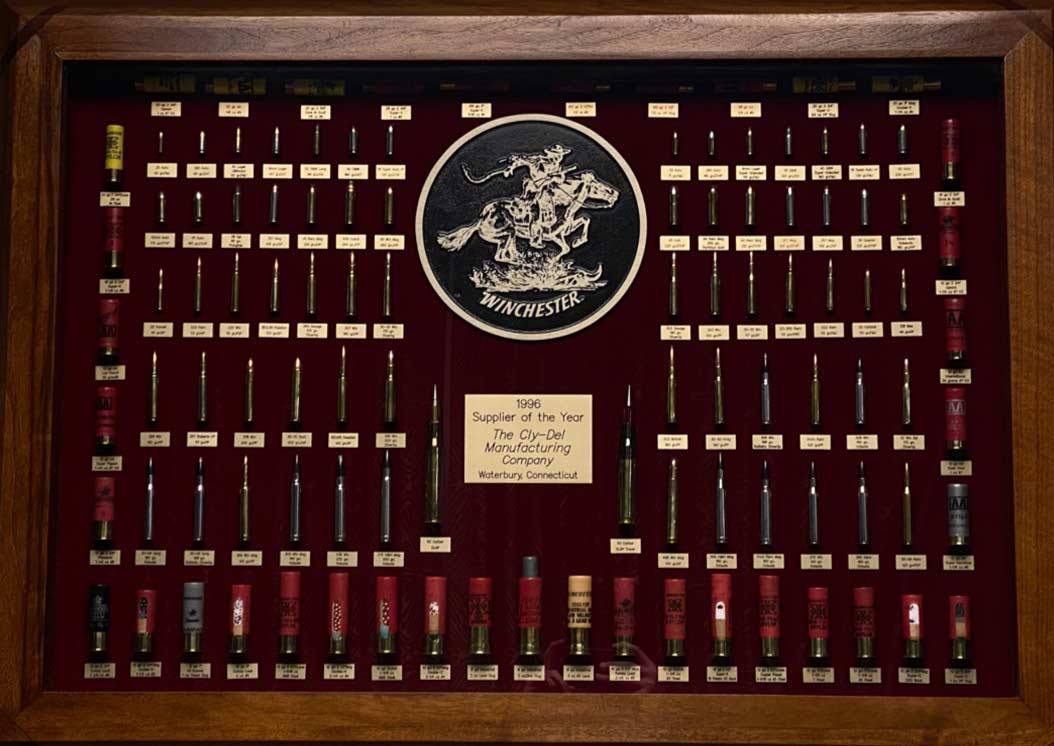

Cly-Del receives Winchester’s Certified Supplier Award for continued excellence in products and services that assist Winchester in meeting customer expectations 100% of the time

1994

Cly-Del named Winchester Supplier of the Year.

1995

The Cly-Del Manufacturing Company named recipient of The Waterbury Foundation’s Traurig Family Award for Philanthropy.

Cly-Del receives Winchester’s Product Components category winner award.

1996

Cly-Del receives the Duracell U.S.A. Award for Quality Improvement.

Cly-Del named Winchester Supplier of the Year.

1997

Robert W. Garthwait Sr. received The Malcolm Baldrige Community Award.

Cly-Del named Duracell Supplier of the Year.

Cly-Del recognized for 50 years of distinguished service to Duracell (1947-1997).

1998

Robert W. Garthwait Sr. received The Florence Martin Chase Award.

2000’s

2002

Cly-Del receives Kids Are Our Business Corporate Benefactor Award.

Cly-Del receives The Gillette Company’s award for outstanding quality and service.

2003

Robert W. Garthwait, Sr. receives The Rev. John P. Blanchfield Community Service Award.

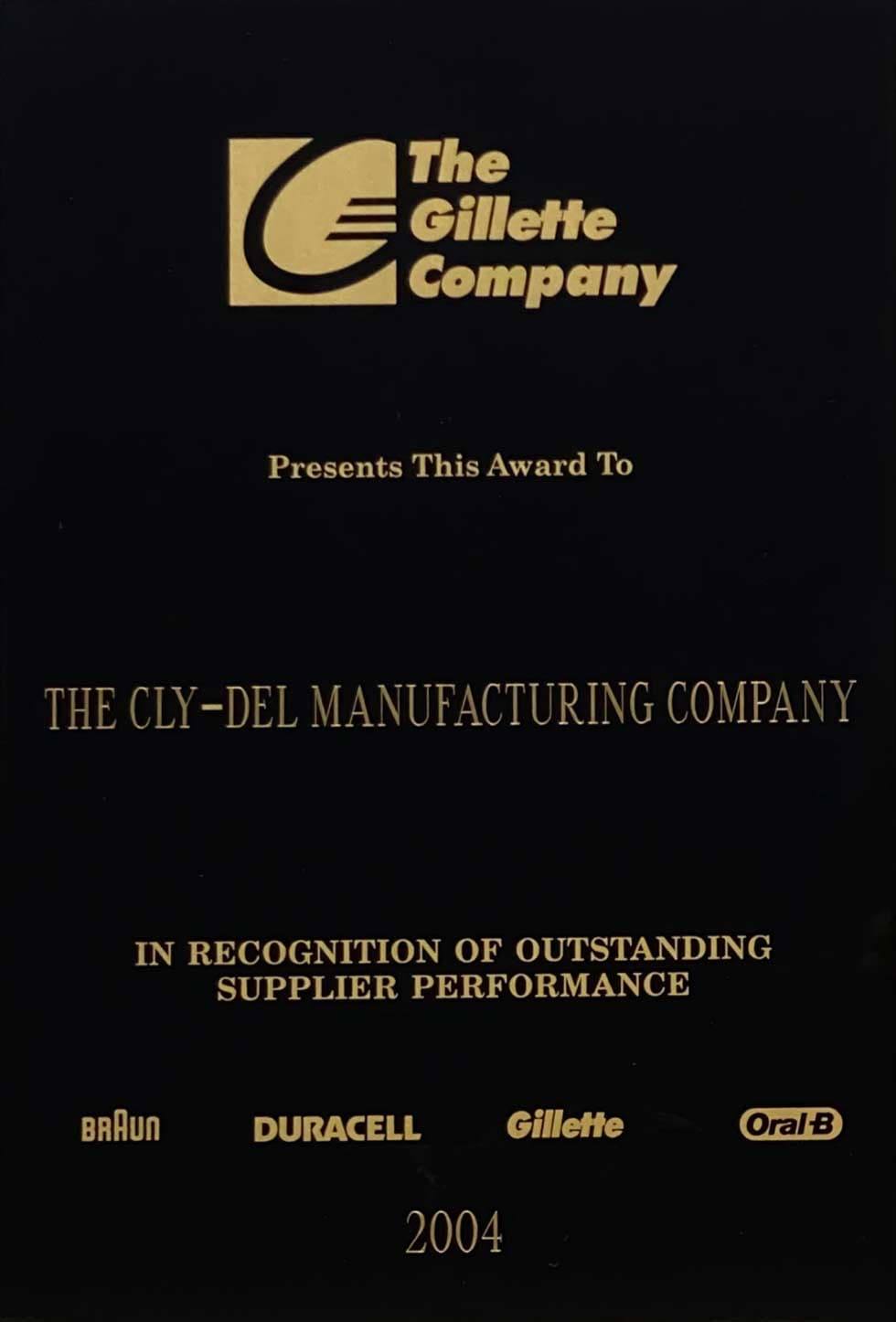

Cly-Del receives The Gillette Company’s award for outstanding quality and service.

2004

Cly-Del receives The Gillette Company’s award for outstanding quality and service.

2005

Cly-Del made the successful acquisition of S&S Dynamic Mfg as Connecticut based specialized Progressive Die house with a broad breadth of product offerings. This continued to diversify and build on Cly-Del’s already vast portfolio of custom produced metal components. Cly-Del continues today to service the legacy S&S type customers with a concentrated effort on stamped products for the Telecom, Lock & Security, Industrial, and Automotive markets.

2006/2007

Procter & Gamble's recognizes Cly-Del for Outstanding Supplier Performance.

2008

Out of 80,000 suppliers, Cly-Del received Procter & Gamble’s Suppliers of the Year award for scoring the highest in broad-based quantitative and qualitative evaluations conducted by the company.

2009

For the second year in a row, Cly-Del is named Procter & Gamble's Suppliers of the Year.

2010’s

2010

Cly-Del receives Procter & Gamble's Supplier of Excellence Award.

2011

Robert W. Garthwait, III worked in the tool room learning the fundamental toolmaking skills while attending Lehigh University as he too was preparing to formally take on his career at Cly-Del.

2013

Cly-Del receives Procter & Gamble's External Business Partner Excellence Awards for consistent high performance.

2018

Debut Indy Car Sponsorship: Here is what Cly-Del Manufacturing CEO Bob Garthwait Jr. had to say about sponsoring Ferrucci and Dale Coyne Racing in these two races:

“We are very excited to sponsor Santino Ferrucci and Dale Coyne Racing at the Portland & Sonoma IndyCar races. Excellence in motorsport requires strong teamwork, precision engineering, and quality execution. These have been our core values at Cly-Del for the last 79 years, making this partnership an outstanding fit. We wish the team well and hope to see more great racing from the series.”

Robert W. Garhtwait, III formally begins his career with the company as its 4th generation, upholding the family legacy at Cly-Del.

2019

May 15, 2019 Robert W. Garthwait Sr. passed.

Robert W. Garthwait Jr. received the Salvation Army Community Service Award.

2020’s

The world has exponentially changed over the last 80 years since Cly-Del was founded as a result of the incredible advances in technology, healthcare, and communications. The rapid rise in the quality of life in the 20th century alone will forever be a testament to the ingenuity, perseverance, and strength of mankind.

Despite a dynamic and ever-changing environment, Cly-Del remains faithful to our guiding values and mission set forth by generations before us. Dedicated specialists and journeyman toolmakers, designers, and engineers transfer expertise and commitment into each and every component we produce. We are proud to present the work of these outstanding specialists, who represent the foundation of our organization. Through perseverance, an uncompromising commitment to quality, and a relentless passion for excellence, Cly-Del continues to deliver the future, today.

Cly-Del’s 4th generation of leadership continues our storied legacy and constant quest for perfection. Relying on an unshakeable faith in human potential, we have renewed calls for an American manufacturing renaissance through apprenticeship programs and vocational education. As always, we draw from tradition to drive innovation, with our history firmly grounded in the present. Cly-Del’s enduring spirit and hope for the future will continue to drive long-lasting success well into the next generation.